Vibro Compaction

Principle of Vibro Compaction

Vibro Compaction (aka Vibroflotation) is the compaction of naturally deposited soils as well as artificially reclaimed sands or gravels by depth vibrators.

The method can compact soils to great depths. The current depth record lies at over 70 meters for reclaimed sands and at 53 meters for naturally deposited sands. The intensity of compaction can be varied to achieve the desired density depending on the foundation needs or ground improvement purpose.

Compaction effects

- The sand and gravel particles rearrange into a denser state

- A significant increase in the horizontal to vertical effective stress ratio

- The permeability of the soil is significantly reduced

- Increased friction angle

- Settlements of the compacted soilmass (between 2% and 15%)

- Increased stiffness modulus

Compaction process

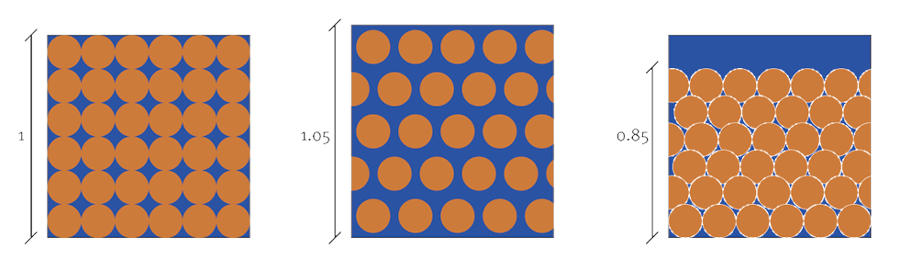

The compaction process consists of a flotation of the soil particles as a result of vibration, which then allows for a rearrangement of the particles into a denser state.

Left: Uncompacted

Middle: In flotation during compaction

Right: Compacted

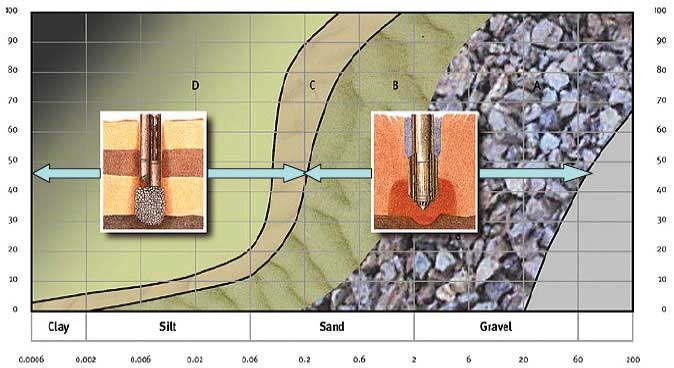

Compactable Soils

Vibro Compaction requires soil with a fines content of less than 12% AND a clay content of less than 1% AND CU = d60/d10 > 2. This soil range is shown in the above graph for soils type A and B. C may be compactable if stone columns are installed, D is not.

Improvement effects

- Increased bearing capacity

- Settlement reduction under loads

- Near–elimination of differential settlements for large foundations

- Liquefaction mitigation

- Prevention of lateral spreading

- Prevention of settlements, due to rearrangement of particles from impacts

- Prevention of (inundation) settlements

- K-value reduction (permeability of soils)

Application of the technology in an optimal manner is an art!

The challenge of optimization lies in the multiple parameters that can be varied and the narrow band in which those parameters need to be adjusted to deliver the desired results. Some of the parameters that can be varied include:

- Type of vibroflot used

- Distance between compaction points

- Hold time per depth interval

- Water pressure

- Location and type of water jets required

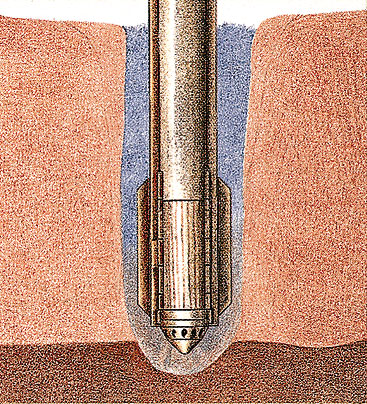

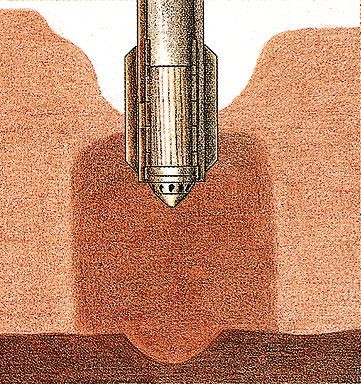

Penetration

By vibration and the flushing of water and/or air, the vibroflot penetrates to the desired depth.

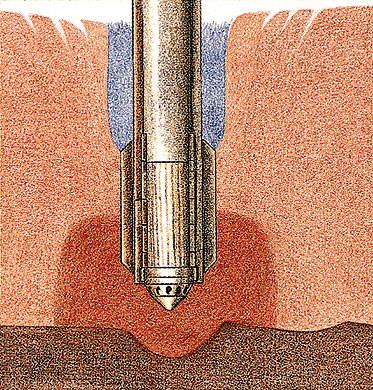

Compaction

The vibroflot is recovered from a certain vertical distance after a verified holding time or buildup of resistance from the compacted ground.

Completion

Immediate top layers may be leveled or impact compacted or roller compacted to ensure a ready-to-build surface.

Movie of Vibro Compaction at Port of Calais, France

The following movie shows a Tandem Vibro Compaction setup during compaction works at the Port of Calais in 2017.

This movie was taken during the initial compaction trials, in which compaction grid, holding time and use of water and air are optimized by our experts.

VIDEO CALAIS

A word on taking movies of vibroflots:

The vibroflots in this movie operate at 1800 RPM (30 Hz) while the movie is shot at 25 frames per second (= 25 Hz). The small difference between the movie frequency and the vibroflot frequency has the effect of slow motion and hence makes the motion of the vibroflots better visible in the movie than with bare eyes on site. The differential movement of the upper, middle and lower parts of the vibroflot tube are an artifact of the scanning made by the video recorder that sequentially scans from top to bottom. This leads to the appearance as if the very stiff steel tubes would be out of rubber.

If the movie had been shot at 30 frames per second, which is the default on mobile phones, the vibroflots in the movie would have made the appearance of standing still.

References for Vibro Compaction

The following globally recognized projects, as well as many similar medium size projects were performed by the members of Betterground in either joint ventures or equipment supply and service arrangements.

Dubai: Palm Jumeirah, Palm Jebel Ali, Dubai Maritime City, Palm Deira, World Dubai Heart of Europe and Iceland (2004 and 2010), Pearl Jumeirah Island (2012), SARB Island (2013), Container Terminal 4 (2016), Palm Jebel Ali (2025), Mina Rashid Marina (2018).

Germany: Lausitz (eng. “Lusatia”) coal mine restoration slope stability projects (1994 to 2006).

Hong Kong:Chek Lap Kok Airport (1995), Central Reclamation (1994 and 2006), West Kowloon Reclamation (1991-1992),

Penny’s Bay (2001-2003).

Mexico: Amanvari Hotel and Resort (2020-2021).

Singapore: Pasir Panjang Container Terminal (1998 – 2000).

World Island Dubai: Vibro Compaction on first showcase island

World Island Dubai: Aerial Photo

Amanvari Hotel and Resort (2020)

Antwerp (2024)

Palm Jebel Ali, Dubai, UAE (2025)

Español

Español